Smart automation for laser sheet handling

Flexible and efficient loading/unloading solutions designed to fit your production flow—whatever your layout.

Astes4 SKYWAY

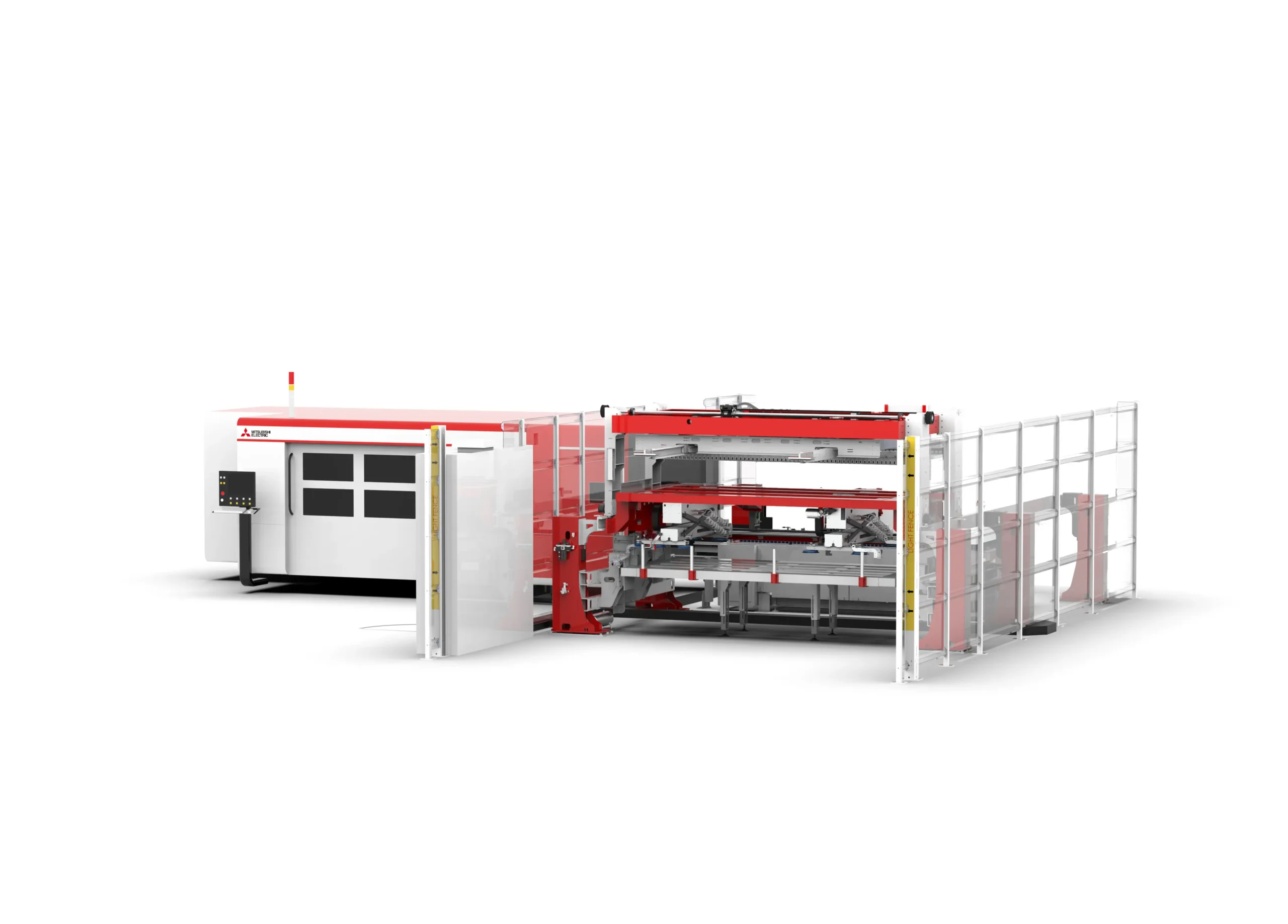

SKYWAY Linear

SkyWay Linear runs parallel to the laser cutting table, delivering an efficient and space-saving layout. Precision, speed, and seamless automation in a compact, high-performing system.

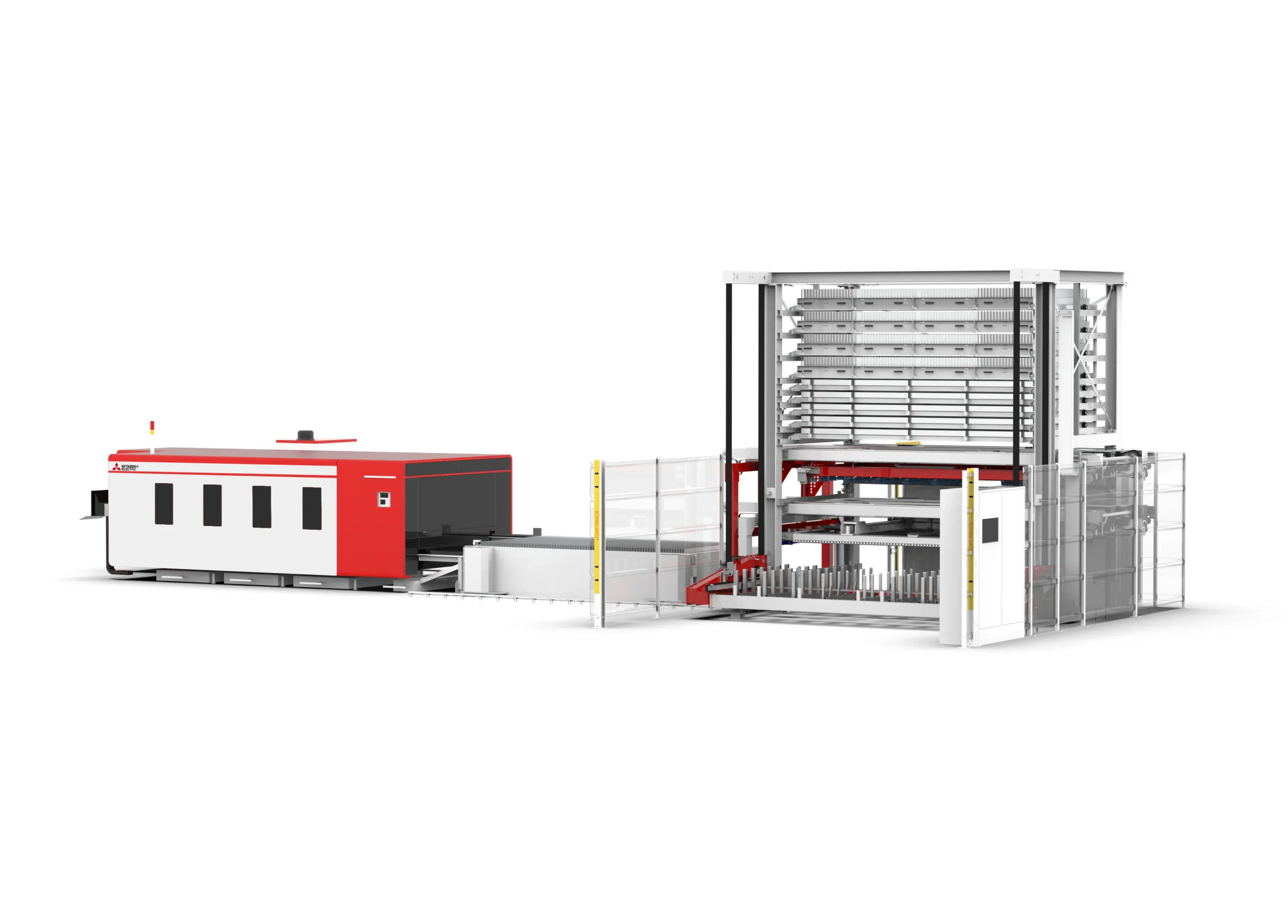

SKYWAY Cross

SkyWay Cross operates perpendicular to the laser table, offering layout flexibility and ultra-fast cycles in a compact, high-performance system. Reliability, adaptability, and advanced integration in one smart solution.

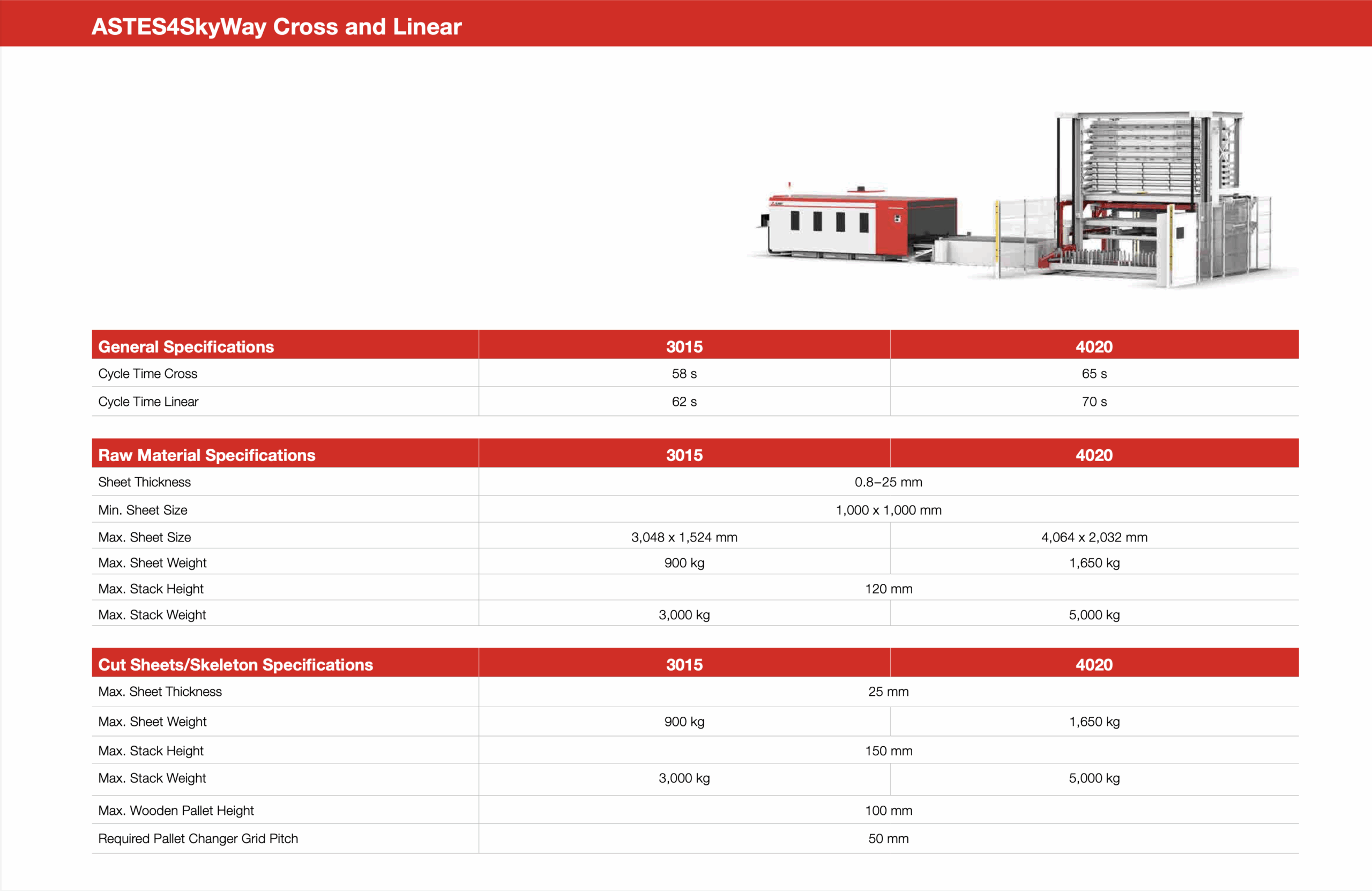

DATA SHEET

Why Choose skyway

SKYWAY LINEAR

In-line integration without compromise

SkyWay Linear is installed along the same line as the laser cutting table, ensuring minimal space usage and an efficient, streamlined material flow—ideal for compact production setups.

Synchronized dual-unit operation

Equipped with two separate manipulators for loading and unloading, SkyWay Linear enables parallel operations, reducing machine idle time and boosting overall productivity. An integrated brushing system cleans the pallet before each load.

Flexible automation with full access

While idle, the system provides full access to the laser’s pallet changer for manual loading or part removal. It can be expanded with ASTES4 sorting and automated storage systems to support lights-out production.

SKYWAY CROSS

Smart integration with full access

SkyWay Cross ensures full access to the pallet changer while optimizing layout flexibility. It’s designed to fit seamlessly into a variety of production environments and can be easily integrated with advanced automation systems.

Fast, synchronized operations

With two independent manipulator units—one for loading and one for unloading—operations run in parallel, achieving a minimal cycle time of 58 seconds (3015 format). The integrated brushing device ensures debris-free pallets, maintaining a stable and continuous workflow.

Flexible and scalable configuration

SkyWay Cross adapts to your layout with multiple setup options. Start with a smart configuration including a raw material table, or scale up to an advanced system with automated carts and full integration into storage solutions.

Seamless integration for any layout

SkyWay systems are designed to adapt to your production flow—whether aligned or offset from the laser cutting table. This flexibility simplifies integration with existing equipment, reduces material handling distances, and keeps the workspace clean and efficient.

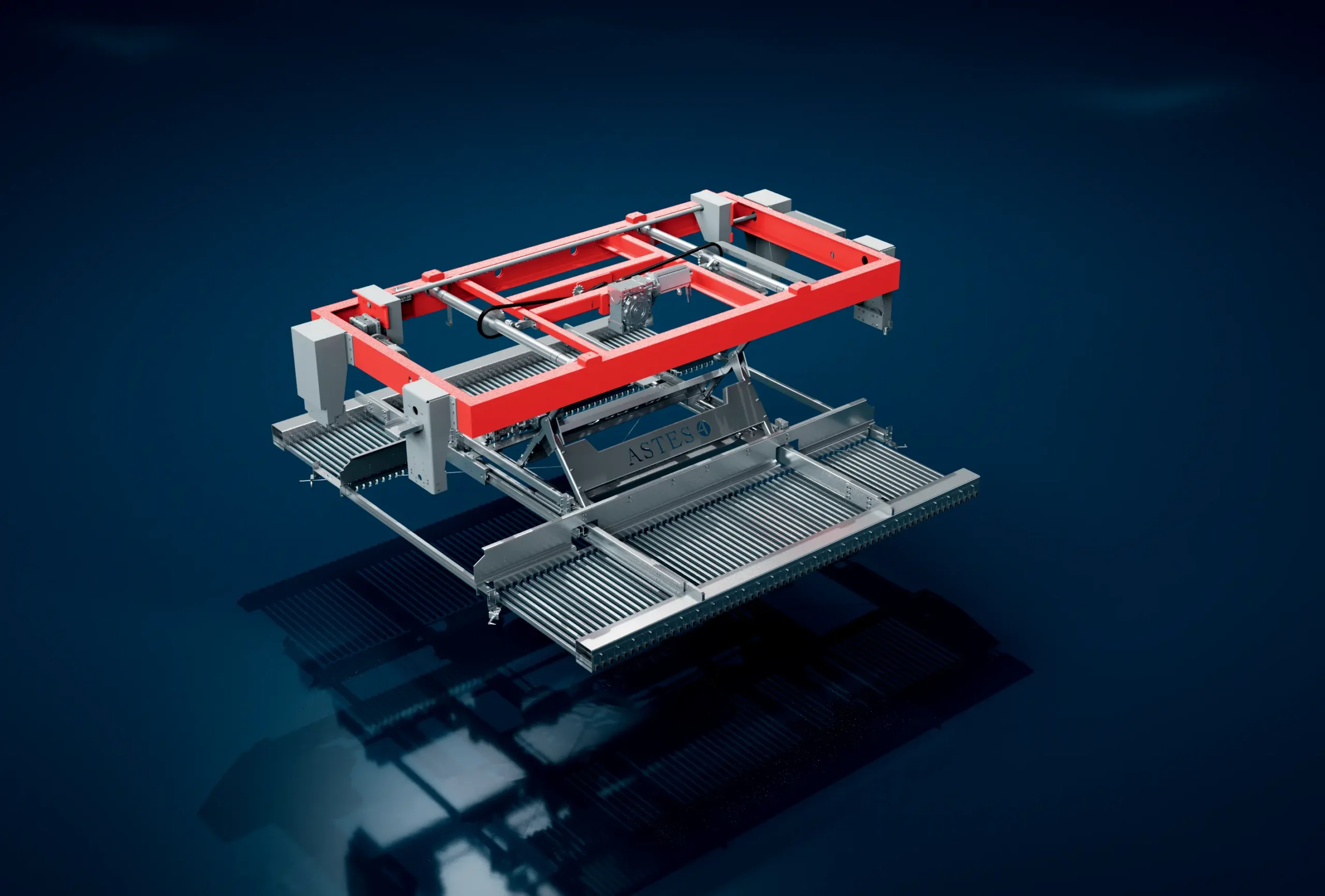

Compact design, advanced automation

Both SkyWay models offer a compact footprint without sacrificing performance. With synchronized loading and unloading cycles, dual manipulator units, and optional brushing systems, SkyWay ensures continuous operation, minimal downtime, and long-term reliability.