Laser Mitsubishi Electric

Are you ready for the future of laser processing? More output, less input.

Mitsubishi Electric beams you to a place where no one has ever lasered before.

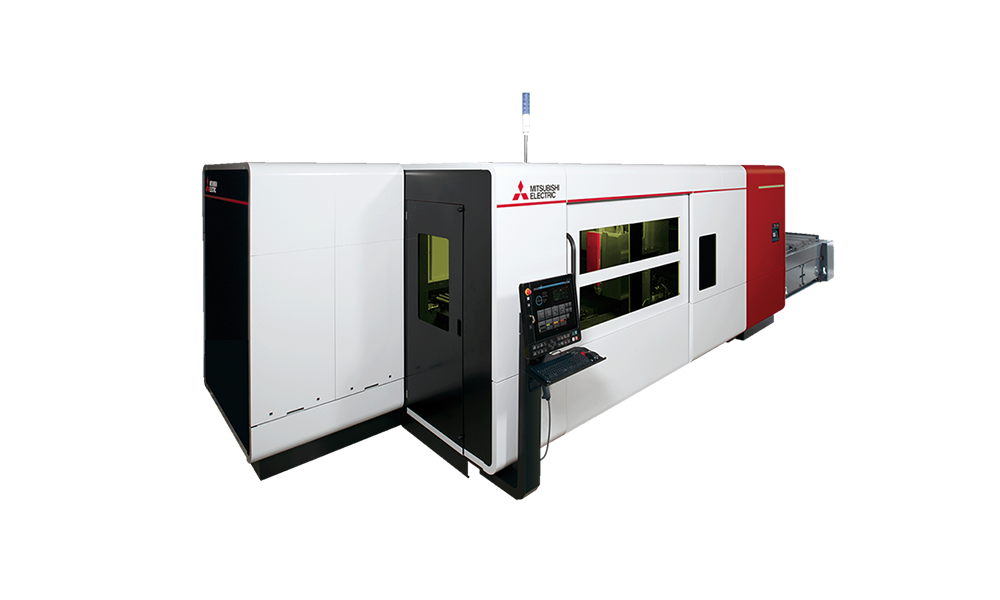

Laser cutting systems of the GX-F series (Fiber)

A masterpiece of artificial intelligence.

Future-ready fiber laser cutting systems with integrated AI, optimized for speed, precision, and energy efficiency. Mitsubishi Electric takes you to a new era of laser processing — smarter, faster, and more cost-effective.

DATA SHEET

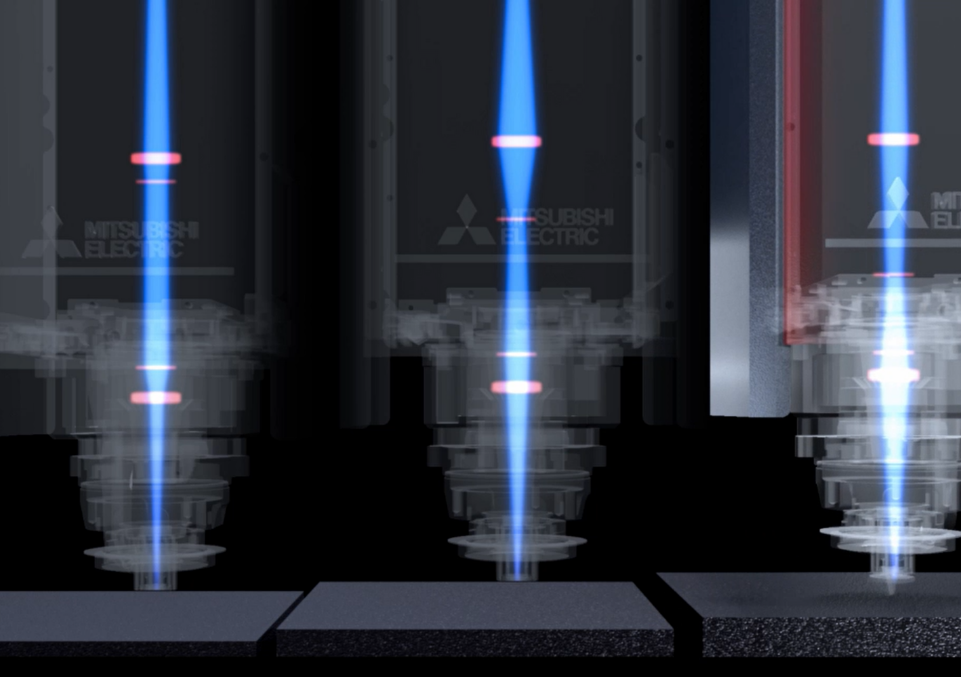

ZoomHead: Laser Precision with Automatic Intelligence

Continuous and Automatic Adjustment Technology

Traditional laser systems often require manual adjustments to the focal point, or frequent parameter changes involving lens replacement (such as 5″, 7.5″, or 10″ lenses) or the use of additional components like extension tubes or secondary optics. These operations are time-consuming and lock the machine into a fixed setup once completed.

With the ZoomHead, all of these adjustments are integrated into a single, intelligent device that allows for fully automatic, manual-free setup and real-time optimization.

Integrated Automatic Functions:

• Adaptive changes based on material type and thickness

• Laser beam diameter adjustment

• Beam shape switching – from point to ring

• Dynamic focal point modification

• Automatic magnification setup

• Continuous and dynamic parameter changes

• Automatic table-based setup without intervention on the head

Also features Automatic Nozzle Changer and AI-based Intelligence for advanced performance.

High Power Piercing (HPP)

Thanks to the integration between Mitsubishi’s fiber laser source and the ZoomHead, ultra-fast piercings are possible:

Up to 25 mm of mild steel pierced in just 0.8 seconds, reducing cycle time by up to 60% compared to traditional systems.

Active Control & Safety

The ZoomHead includes the MEL’s EYE system, which monitors the cutting process in real time and detects anomalies such as:

• Incomplete piercing

• Excessive plasma

• Burn marks

• Loss of cut

Additionally, the DRC (Dross Reduction Control) system improves edge quality by minimizing slag formation.

Smart Magnetic Protection

A unique magnetic mechanism holds the cutting head in place and automatically resets it after accidental impact. This system:

• Reduces machine downtime

• Prevents structural damage

• Eliminates the need for manual nozzle realignment

Protective Glass Monitoring

An internal sensor continuously checks the condition of the protective glass, alerting the operator in case of contamination or when replacement is required — ensuring optimal laser beam quality at all times.

Automatic Protective Glass Replacement

(New for 2025)

Available on many of our models, this new 2025 feature allows for automatic replacement of the protective glass — a major step forward in reducing maintenance time and increasing uptime.

AGR-MIX: High-Quality Cutting, Lower Gas Consumption

Mitsubishi Laser introduces AGR-MIX, a next-generation, patented technology integrated into GX-F series fiber lasers with built-in AI intelligence. This innovative solution significantly reduces assist gas consumption and improves cutting quality on ferrous materials by minimizing or eliminating dross formation.

No External Tanks, Maximum Efficiency

The newly designed AGR-MIX nozzle eliminates the need for external mixing tanks or high-pressure oxygen. Instead, it mixes compressed air and nitrogen directly inside the nozzle, generating an optimized gas flow that adapts in real time based on the material being processed.

Up to 75% Gas Savings

Derived from Mitsubishi’s AGR (Assist Gas Reduction) technology, AGR-MIX enables up to 75% nitrogen savings, with the potential for an additional 50% reduction in specific conditions. A substantial decrease in operating costs for any production environment.

A Complete Range for Every Cutting Need

Mitsubishi Laser offers three optimized assist gas reduction technologies:

• AGR-N2 – Oxide-free cutting, 100% nitrogen, up to 75% savings

• AGR-AIR – Air cutting, highly cost-effective

• AGR-MIX – Optimized mixed gas cutting for high quality and further savings

These solutions meet growing demands for efficiency and lower nitrogen consumption.

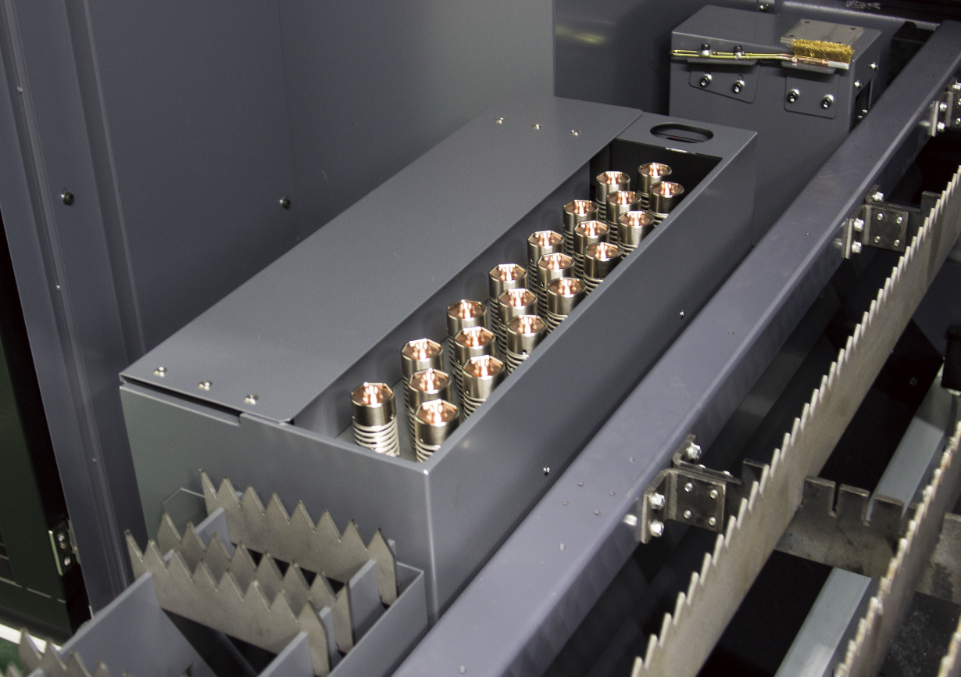

Innovative Double-Chamber Nozzle Design

The AGR-MIX nozzle features a dual-chamber configuration: nitrogen is directed through the center, surrounded by an outer flow of air. Part of this air is redirected into the main flow to create the MIX gas stream—ensuring greater cut stability and cleaner results, even on high-volume jobs.

Proven Results and Consistent Quality

Users of AGR-MIX report stable production, repeatable results, and excellent cut quality, particularly on mild steel. This technology is designed to deliver consistent performance while reducing operational costs.

Smart, Hands-Free Nozzle Switching

The GX-F series offers an optional automatic nozzle changer — a 2025 innovation — that allows the system to switch nozzles without operator intervention. This reduces downtime, ensures optimal setup for every material type, and contributes to fully automated production.

High-Power, Integrated Laser Source

GX-F systems are equipped with Mitsubishi Electric fiber oscillators ranging from 4 to 20kW. Designed for precision and endurance, these oscillators deliver consistent high-speed cutting — with minimal maintenance and optimal integration with the ZoomHead and AGR systems.

Advanced Intelligence & Safety Features